Exploring the realm of Fleet Preventive Maintenance, this introduction sets the stage for a deep dive into how proper maintenance practices can lead to cost savings and increase the longevity of fleet vehicles. The economic aspects of preventive maintenance are crucial in understanding the overall efficiency of fleet management.

Importance of Fleet Preventive Maintenance

Preventive maintenance is crucial in fleet management as it helps in ensuring the smooth operation of vehicles and reducing the likelihood of unexpected breakdowns. By conducting regular maintenance checks and servicing, fleet managers can identify and address potential issues before they escalate, saving both time and money in the long run.

Cost Savings Through Proper Maintenance

- Regular maintenance can help prevent major repairs that may be costly.

- Well-maintained vehicles are more fuel-efficient, leading to savings on fuel costs.

- Avoiding breakdowns through preventive maintenance can prevent expensive towing fees and rental vehicle costs.

Improvement in Lifespan of Fleet Vehicles

- Proper maintenance can extend the lifespan of fleet vehicles, reducing the frequency of replacements.

- Regular servicing can help in detecting and addressing issues early on, preventing premature wear and tear.

- Increased longevity of vehicles means a higher return on investment for the fleet owner.

Cost Analysis of Fleet Preventive Maintenance

Investing in preventive maintenance for fleets can lead to significant economic benefits in the long run. By regularly servicing vehicles and addressing potential issues before they escalate, companies can avoid costly breakdowns, reduce downtime, and extend the lifespan of their fleet.

Cost Comparison: Preventive vs. Reactive Maintenance

- Preventive Maintenance:

- Regularly scheduled maintenance tasks such as oil changes, tire rotations, and inspections.

- Costs are predictable and spread out over time, avoiding sudden and expensive repairs.

- Reduces the likelihood of major breakdowns and associated costs.

- Reactive Maintenance:

- Repairs are done only when a vehicle breaks down or shows signs of malfunction.

- Costs can be unpredictable and often higher due to emergency repairs and downtime.

- Increases the risk of larger and more costly repairs due to neglecting minor issues.

Potential Cost Savings through Regular Maintenance Practices

Regular preventive maintenance can result in various cost savings for fleet operations:

- Reduced Repair Costs:

- Identifying and fixing minor issues early can prevent them from developing into major problems, saving on repair expenses.

- Increased Vehicle Lifespan:

- Proper maintenance can extend the life of vehicles, delaying the need for costly replacements.

- Improved Fuel Efficiency:

- Well-maintained vehicles tend to operate more efficiently, saving on fuel costs over time.

- Enhanced Safety:

- Regular maintenance ensures that vehicles are in optimal condition, reducing the risk of accidents and associated costs.

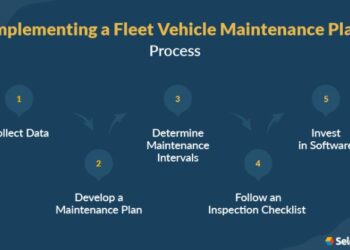

Key Components of a Fleet Preventive Maintenance Program

Preventive maintenance programs are crucial for ensuring the longevity and efficiency of fleet vehicles. By implementing an effective preventive maintenance program, fleet managers can minimize downtime, reduce repair costs, and improve overall fleet performance. Let's delve into the key components of a successful preventive maintenance program.

Identifying Essential Components

When it comes to preventive maintenance programs for fleets, several essential components need to be in place:

- Regular Inspections: Conducting routine inspections on fleet vehicles to identify potential issues before they escalate.

- Scheduled Maintenance Tasks: Establishing a detailed schedule for maintenance activities such as oil changes, tire rotations, and fluid checks.

- Record Keeping: Maintaining accurate records of all maintenance activities, including dates, services performed, and any issues detected.

- Training and Education: Providing ongoing training for drivers and maintenance staff on the importance of preventive maintenance and how to spot early warning signs.

- Compliance with Manufacturer Guidelines: Adhering to manufacturer recommendations for maintenance intervals and procedures to ensure warranty compliance and optimal performance.

Scheduling Maintenance Tasks for Optimization

Properly scheduling maintenance tasks is key to optimizing fleet operations and minimizing disruptions. By strategically planning maintenance activities based on vehicle usage, mileage, and operating conditions, fleet managers can ensure that vehicles remain in peak condition and avoid unexpected breakdowns.

Role of Technology in Modern Programs

Technology plays a significant role in modern preventive maintenance programs for fleets. Fleet management software, telematics systems, and IoT devices enable real-time monitoring of vehicle health, performance analytics, and automated alerts for maintenance reminders. By leveraging technology, fleet managers can proactively address maintenance needs, streamline processes, and make data-driven decisions to enhance fleet efficiency.

Impact of Preventive Maintenance on Downtime and Productivity

Preventive maintenance plays a crucial role in reducing downtime for fleet vehicles and increasing overall productivity. By regularly servicing and inspecting vehicles, potential issues can be identified and addressed before they escalate into major problems that require extensive repairs. This proactive approach helps in minimizing unexpected breakdowns and the subsequent downtime associated with them.

Reduced Downtime

- Regular maintenance schedules help in keeping fleet vehicles in optimal condition, reducing the likelihood of unexpected breakdowns.

- Timely replacement of worn-out parts and fluids prevents sudden failures that could result in extended downtime.

- Scheduled inspections allow for the early detection of potential issues, enabling repairs to be carried out before they lead to significant downtime.

Improved Productivity

- Well-maintained vehicles are more reliable and efficient, leading to fewer disruptions in operations and increased productivity.

- Properly maintained fleet vehicles are less likely to experience delays or breakdowns during crucial tasks, ensuring smooth operations.

- Regular maintenance contributes to the longevity of vehicles, reducing the need for frequent replacements and downtime associated with acquiring new assets.

By investing in preventive maintenance, fleet managers can significantly reduce downtime, increase operational efficiency, and ultimately enhance the productivity of their fleets.

Conclusive Thoughts

In conclusion, The Economics of Fleet Preventive Maintenance showcases the tangible benefits of investing in proactive maintenance strategies for fleets. By reducing downtime, improving productivity, and optimizing costs, preventive maintenance emerges as a key factor in ensuring the smooth operation of fleet vehicles.

FAQ Corner

What are the key benefits of preventive maintenance for fleets?

Preventive maintenance helps in reducing unexpected breakdowns, saving costs in the long run, and extending the lifespan of fleet vehicles.

How does preventive maintenance impact fleet productivity?

Regular maintenance ensures that fleet vehicles are in optimal condition, leading to enhanced productivity and efficiency in operations.

![How To Repair Car Hail Damage? [Easy Ways With Steps]](https://vehicle.infogarut.id/wp-content/uploads/2025/11/7496bef49d9c9080663199225093865c-120x86.jpg)